To measure a band saw blade, determine the correct length by measuring the distance between the two wheels, taking into account any wheel adjustments. Choose the appropriate blade width, thickness, tooth configuration, and material based on your band saw specifications and project requirements.

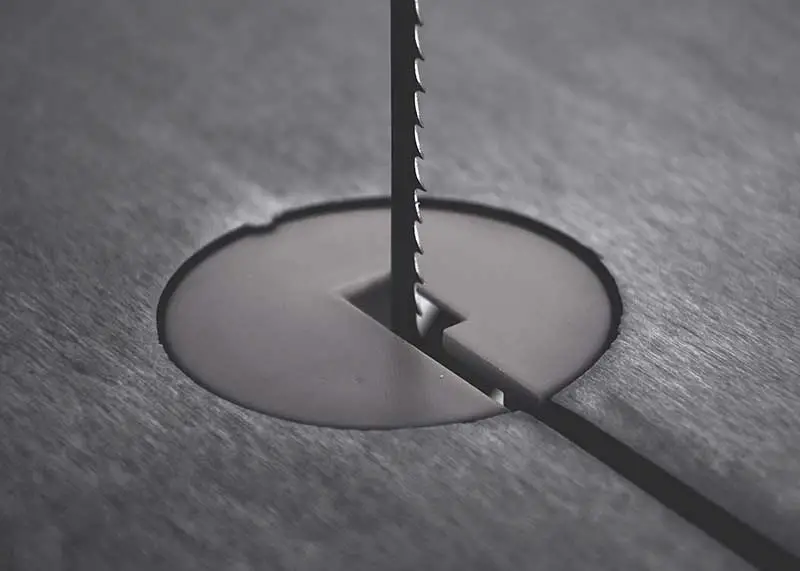

Band saw blades are an essential component of any band saw, and it’s important to choose the right size for your specific machine to ensure proper performance and accurate cuts. Here’s a step-by-step guide on how to measure band saw blades without a manual.

Determine the Length

The first measurement to consider is the blade’s length. To determine the correct blade length for your band saw, follow these steps:

- Measure the wheel distance: Measure the distance between the two wheels on your band saw. Place a flexible measuring tape or a string around the wheels, following the same path the blade would take. Make sure the tape or string is tight and record the measurement.

- Account for wheel adjustments: Some band saws have adjustable wheels that can accommodate different blade lengths. If your band saw has this feature, adjust the wheels to the desired position and re-measure the distance.

Determine the Blade Width

The blade width is important for the types of cuts you’ll be making on your band saw. Wider blades are suitable for straight cuts and resawing, while narrower blades are ideal for cutting curves and intricate designs. To choose the right width, consider the following:

- Check the band saw specifications: Look for any markings or labels on your band saw that might provide information about the maximum and minimum blade widths it can accommodate. If you can’t find any markings, search online for the make and model of your band saw to find specifications.

- Consider the project requirements: Choose a blade width that matches the type of cuts you’ll be making. For example, if you’re cutting tight curves, opt for a narrower blade. If you’re resawing lumber, choose a wider blade for better stability and straighter cuts.

Determine the Blade Thickness

The blade thickness, or gauge, affects the durability and cutting performance of your band saw blade. Thicker blades are more rigid and less prone to breakage but may be less suitable for intricate cuts. To determine the appropriate blade thickness:

- Check the band saw specifications: Like blade width, look for markings or labels on your band saw that provide information about the suitable blade thicknesses. If you can’t find any markings, search online for the make and model of your band saw to find specifications.

- Consider the material and project requirements: Choose a blade thickness based on the material you’ll be cutting and the precision required for your project. Thinner blades may be more appropriate for cutting thin materials or delicate work, while thicker blades may be better for cutting thicker or harder materials.

After determining the length, width, and thickness of the band saw blade you need, choose a blade with the appropriate tooth configuration and material for your specific cutting application.

Selecting the Right Tooth Configuration

The tooth configuration of a band saw blade plays a crucial role in determining the quality of the cut and the type of material it can handle. There are several tooth configurations to choose from, each designed for specific tasks:

- Standard tooth: A regular tooth configuration with evenly spaced teeth, ideal for general-purpose cutting of wood, metal, and plastic.

- Hook tooth: A tooth configuration with larger gullets and a positive rake angle, suitable for aggressive cuts in thicker materials like hardwood and metal.

- Skip tooth: A tooth configuration with wide gullets and a neutral rake angle, designed for cutting softer materials like softwood and non-ferrous metals.

- Variable tooth: A tooth configuration with a varying set pattern and pitch, resulting in reduced vibration and noise. Ideal for cutting a wide range of materials and thicknesses.

Consider the type of material you’ll be cutting and the desired quality of the cut when selecting the appropriate tooth configuration.

Choose the Blade Material

Band saw blades come in various materials, each with its own characteristics and benefits. Some common materials used for band saw blades include:

- Carbon steel: An affordable option, suitable for cutting wood, plastic, and non-ferrous metals. Carbon steel blades are ideal for hobbyists and occasional users.

- Bi-metal: A combination of high-speed steel teeth and a flexible carbon steel backing, bi-metal blades are more durable and long-lasting than carbon steel blades. They are suitable for cutting a wide range of materials, including wood, metal, and plastic.

- Carbide-tipped: Blades with carbide tips offer superior durability and cutting performance, making them ideal for cutting hard and abrasive materials like hardwood, laminates, and composite materials.

| Measurement | Considerations |

|---|---|

| Blade Length | Wheel distance, wheel adjustments |

| Blade Width | Band saw specifications, project requirements |

| Blade Thickness | Band saw specifications, material, and project requirements |

| Tooth Configuration | Material type, desired cut quality |

| Blade Material | Material type, durability, cutting performance |