Key Takeaways

- Band saws are versatile tools used for cutting intricate shapes, resawing, and ripping materials in woodworking projects.

- Proper setup and safety measures are crucial to achieve accurate cuts and prevent accidents.

- Mastering basic and advanced cutting techniques will help you get the most out of your bandsaw.

- Regular maintenance, including blade replacement and alignment, ensures the longevity and optimal performance of your bandsaw.

- When buying a bandsaw, consider factors such as size, brand, and accessories to make an informed decision.

How Much is a Band Saw?

Band saw prices can range from under $200 for benchtop models to over $4,000 for large floor-standing models, depending on factors such as size, power, and features. When considering the cost of a band saw, it’s important to factor in not only the initial purchase price but also the long-term costs associated with maintenance, replacement blades, and accessories.

“Remember, investing in a quality band saw can save you money in the long run by providing more accurate cuts and reducing the need for frequent repairs or replacements.”

When shopping for a band saw, be sure to compare the features and specifications of various models within your budget to ensure you are getting the best value for your money. Some features to consider include motor power, cutting capacity, and ease of blade changes. Additionally, look for reviews from professionals and hobbyists alike to get a sense of the saw’s performance and reliability.

It’s also important to remember that while a higher price tag may indicate better quality, it doesn’t always guarantee the best fit for your needs. Consider your intended usage and projects before making a final decision, and don’t be afraid to invest in a more affordable model if it meets your requirements.

In conclusion, the cost of a band saw can vary greatly, but it’s crucial to assess the features, performance, and long-term value before making a purchase. By doing so, you’ll ensure you get the best band saw for your specific needs and budget.

What Size Band Saw Do I Need?

The size of the band saw you need depends on the types of projects you plan to work on and the space available in your workshop. Generally, band saws are categorized by their throat capacity (the distance between the blade and the frame) and the depth of cut (the maximum thickness of material that can be cut).

“Selecting the right size band saw is crucial for efficient and accurate cutting, as well as maximizing your workspace.”

Here are some common band saw sizes and their typical applications:

Table 1: Common Band Saw Sizes and Applications

| Band Saw Size | Throat Capacity | Depth of Cut | Best For |

|---|---|---|---|

| 9-inch | 9 inches | 3-1/2 inches | Small projects, hobbyists, and limited workspace |

| 14-inch | 14 inches | 6-8 inches | Moderate projects, DIYers, and small professional shops |

| 17-inch | 17 inches | 10-12 inches | Larger projects, heavy-duty work, and professional shops |

| 21-inch | 21 inches | 12-14 inches | Industrial applications and serious woodworking enthusiasts |

Caption: This table provides an overview of popular band saw sizes and their ideal uses.

To determine the appropriate size for your needs, consider the types of materials you plan to cut and the maximum dimensions you anticipate needing. For instance, if you mostly work with small to medium-sized projects and have limited space in your workshop, a 9-inch or 14-inch band saw may be sufficient. On the other hand, if you frequently cut large pieces of lumber or require more power and capacity for heavy-duty work, a 17-inch or 21-inch model would be more suitable.

Another factor to consider when choosing the right size is the availability of band saw blades. Some band saw sizes have more blade options available, which can affect the versatility of the saw. For example, 14-inch band saws are quite popular, making it easier to find replacement blades and accessories that fit this size.

It’s also essential to consider the power of the motor, as larger band saws require more powerful motors to handle bigger cuts and thicker materials. Smaller band saws typically have motors ranging from 1/3 to 1 horsepower, while larger models can have motors up to 3 horsepower or more. Ensure the motor is strong enough to handle the materials you plan to cut without overloading or damaging the saw.

Considering these factors, along with your project requirements, available workspace, and budget, will help you make the most informed decision when selecting the size of your band saw.

Comparing Band Saw Brands: WEN 9-inch Bandsaw Review

When choosing a band saw, comparing different brands and models is essential for finding the perfect fit for your needs and budget. One popular choice for hobbyists and DIYers is the WEN 9-inch bandsaw, known for its affordability, compact size, and reliable performance.

“The WEN 9-inch bandsaw is an excellent choice for those looking for an affordable and space-saving solution for smaller woodworking projects.”

WEN 9-inch Bandsaw Features

Table 2: WEN 9-inch Bandsaw Specifications

| Feature | Specification |

|---|---|

| Throat capacity | 9 inches |

| Depth of cut | 3-1/2 inches |

| Motor | 2.8 amp, 1/3 HP |

| Blade size | 62 inches |

| Two-speed operation | 1520 and 2620 FPM |

| Bevel capacity | 0 to 45 degrees |

| Table size | 12 x 12 inches |

| Dust port | 2-1/2 inches |

Caption: An overview of the key features and specifications of the WEN 9-inch bandsaw.

The WEN 9-inch bandsaw is an ideal option for those with limited space in their workshop or who primarily work on smaller projects. Its compact design, affordable price, and user-friendly features make it an attractive option for beginners and experienced woodworkers alike.

In terms of performance, the WEN 9-inch bandsaw offers a reliable cutting experience. The 2.8 amp, 1/3 HP motor provides sufficient power for cutting various materials, such as wood, plastic, and soft metals. The two-speed operation allows users to adjust the blade speed according to the material being cut, ensuring clean and precise results.

The bandsaw’s bevel capacity ranges from 0 to 45 degrees, allowing for angled cuts and increased versatility in woodworking projects. Additionally, the 12 x 12-inch table provides a stable work surface and can be easily adjusted to accommodate different material thicknesses.

One downside of the WEN 9-inch bandsaw is its limited throat capacity and depth of cut, which may not be sufficient for larger projects or more advanced woodworking tasks. However, for hobbyists and DIYers working with smaller materials, this bandsaw offers excellent value for the price.

When comparing band saw brands and models, it’s crucial to consider your specific needs, budget, and available workspace. While the WEN 9-inch bandsaw is an excellent choice for those with smaller requirements, it’s essential to explore other options and read reviews to find the best band saw for your unique circumstances.

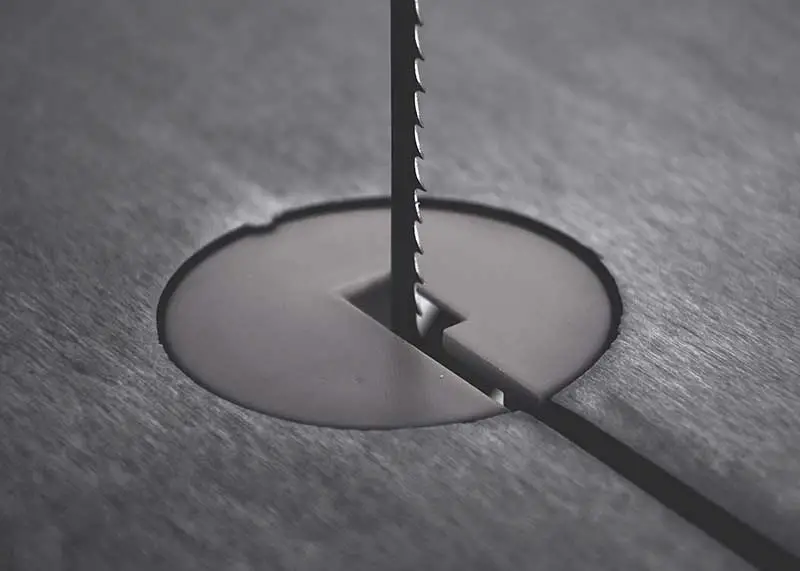

Band Saw Blade Guard: Importance and Options

A band saw blade guard is essential for safety, as it helps prevent accidents and ensures proper blade alignment. There are various options available, including built-in guards and aftermarket add-ons.

Band saw blade guards serve two primary purposes: protecting the user from accidental contact with the blade and ensuring the blade’s alignment remains accurate during cutting. When operating a band saw, it’s crucial to have a reliable and efficient blade guard to minimize the risk of injury and improve cutting accuracy.

“A well-designed blade guard will not only keep you safe but also help you achieve cleaner, more accurate cuts.”

There are different types of blade guards available, depending on the specific needs and requirements of the user. Some of the most common types include:

- Built-in guards: Many band saws come with built-in blade guards, which are usually adjustable and can be moved up or down to accommodate the thickness of the material being cut. These guards are designed to work seamlessly with the saw and are typically made of metal or heavy-duty plastic.

- Aftermarket add-ons: For users who want additional safety features or an upgraded blade guard, aftermarket add-ons are available. These products are designed to be easily installed on a variety of band saw models and can provide enhanced protection and functionality. Some popular options include magnetic blade guards, quick-release guards, and clear, polycarbonate guards.

Remember, a properly adjusted and maintained band saw blade guard is crucial for ensuring safe and accurate cuts.

When choosing a blade guard, consider factors such as compatibility with your specific band saw model, ease of installation, and adjustability. No matter which type of guard you choose, always make safety a top priority when working with power tools.

Band Saw Accessories and Jigs to Enhance Your Workspace

Band saw accessories and jigs can significantly improve the versatility and efficiency of your workspace. From fence systems to circle-cutting jigs, investing in the right accessories can make your band saw even more useful.

A well-equipped band saw workstation can make your woodworking projects much more efficient and enjoyable. By adding some essential accessories and jigs to your setup, you can unlock the full potential of your band saw. Here are some popular options to consider:

“The right accessories and jigs can turn your band saw into a versatile and efficient cutting machine.”

- Fence systems: A band saw fence system helps you make straight and precise cuts by providing a stable reference edge. Some band saws come with a built-in fence, but you can also purchase aftermarket options that are adjustable and easy to install.

- Circle-cutting jigs: If you need to cut perfect circles or arcs, a circle-cutting jig is an invaluable accessory. These jigs attach to the band saw table and allow you to make consistent and accurate circular cuts with ease.

- Miter gauges: For making accurate angled cuts, a miter gauge is essential. This accessory slides into the miter slot on the band saw table and can be adjusted to various angles, allowing you to make precise crosscuts and bevel cuts.

- Resaw guides: Resawing is the process of cutting a board into thinner pieces, and a resaw guide helps you do this accurately and safely. Resaw guides typically clamp onto the band saw’s fence and provide support for the workpiece during the cutting process.

- Blade tension meters: Maintaining proper blade tension is crucial for accurate cuts and blade longevity. A blade tension meter measures the tension on the band saw blade, helping you ensure it’s set correctly.

Table 2: Popular Band Saw Accessories and Jigs

| Accessory/Jig | Purpose |

|---|---|

| Fence systems | Provides a stable reference edge for straight and precise cuts |

| Circle-cutting jigs | Enables consistent and accurate circular cuts |

| Miter gauges | Allows for precise angled crosscuts and bevel cuts |

| Resaw guides | Supports workpiece during the resawing process |

| Blade tension meters | Measures blade tension to ensure proper settings |

A summary of popular band saw accessories and jigs to enhance your workspace.

When selecting accessories and jigs for your band saw, make sure they are compatible with your specific saw model and meet your woodworking needs. By investing in the right accessories, you can enhance your workspace and get more out of your band saw.

How to Find Bandsaw Parts and Services Near You

Locating bandsaw parts and services near you is essential for maintaining your machine and ensuring its longevity. To find a reliable provider, follow these steps:

- Search online: Start by conducting a simple online search using terms like “bandsaw parts” or “bandsaw services” along with your location.

- Check reviews: When you find potential providers, read customer reviews and testimonials to gauge their reputation and reliability.

- Ask for recommendations: Consult fellow woodworkers, friends, or family members who may have experience with bandsaw parts and services.

- Visit local hardware stores: Many local hardware stores carry bandsaw parts and can also recommend service providers.

- Contact the manufacturer: Reach out to the manufacturer of your bandsaw for guidance on locating authorized dealers and service centers.

“Don’t forget to maintain your bandsaw regularly to prevent any serious issues from arising.“

Remember, proper maintenance and timely repairs will keep your bandsaw in top condition, ensuring a smooth and efficient woodworking experience. Regularly inspect your bandsaw for wear and tear, and replace any damaged parts as needed.

Some commonly replaced parts include blades, tires, guides, and bearings. When searching for parts, ensure compatibility with your specific bandsaw model to avoid complications or damage.

Conclusion

Band saws are an essential tool for any serious woodworker, offering versatility and precision in cutting various materials. By understanding the basics of using a bandsaw, mastering advanced techniques, and maintaining your machine, you can ensure your woodworking projects are completed efficiently and accurately. With proper care and attention, your bandsaw will be a valuable addition to your workshop for years to come.